How Acta Marine is drastically reducing its carbon footprint

Decarbonization is quickly becoming an imperative for businesses and society. The transition to more sustainable forms of energy is already well underway in our electricity grids, and beginning to take hold in other areas such as transport.

In the maritime world, attitudes are also changing quickly; in a recent report from Shell and Deloitte, over 90% of respondents from across the industry said decarbonization is an important or top priority for their organizations.

However, there is a rather large fly in the ointment. In the short-medium term, the maritime industry is difficult to decarbonize completely, due to factors such as long asset lifespans, high energy dependency, and complexity of electrification. But on the other hand, there is an enormous potential to lower our carbon footprints and run vessels more efficiently today, with technology that is already available.

In this interview, we talk to an organization that has already taken practical steps and is achieving a dramatic reduction in their carbon footprint. Acta Marine is an offshore logistics support provider specialized in supplying energy infrastructure, and we spoke to Cor Visser, General Manager Operations, about their decision to partner with Onboard, how they are reducing their fuel consumption, and larger trends around sustainability in the industry.

Welcome Cor! Maybe we can start with a little about Acta Marine’s goals around sustainability.

Yes sure. So the whole world is moving towards a more sustainable future, it’s a global megatrend. And Acta Marine is no exception. Like many other companies, we have firm goals around sustainability, and are actively working on challenges like green energy and lowering our carbon footprint. But we have another issue specific to one of our key customers of 25 years, Wintershall Dea. This customer operates on Mittelplate, Germany’s largest crude oil field, in an ecologically protected area listed by UNESCO. Operations in this area are particularly sensitive, and when serving this customer it is even more critical to be as sustainable and responsible as possible.

One other important thing to note here is that our initiatives around sustainability and lowering our carbon footprint are not primarily driven by cost savings. They are driven also by the overall trend toward transparency in the industry, and our end customers demanding better ways of doing things. The world is moving quickly in this direction and we want to be ahead of the curve.

What Onboard solutions are you using?

We have Onboard Servers installed on four vessels - two for supply, one crew tender, and one Walk 2 Work vessel. The servers collect the required data to help us make smart decisions to reduce fuel consumption, primarily through the Fuel Efficiency app.

Why did you start to work with Onboard for fuel efficiency specifically?

Wintershall Dea is a key customer of ours and we have a very productive relationship. But of course, as a partner and supplier, we are always looking for ways to strengthen the relationship. As mentioned, lowering our carbon footprint is critically important to Wintershall Dea. We had many ideas on how to reduce fuel consumption, but at the end of the day lacked the hard data to prove them. Ultimately, our ideas were no better than feelings. But with Onboard we realized we would be able to make objective decisions about and a holistic approach to fuel efficiency and show the results.

“With Onboard we realized we would be able to make objective decisions about fuel efficiency and show the results."

Can you walk us through how you use the app, and who has access to the data?

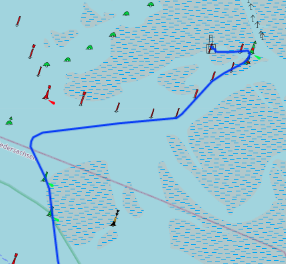

The platform in the Mittelplate oil field is located in a shallow draft area, so timing the tide is important. In addition the current from the nearby mouth of the Elbe river is very strong. And of course the wind can have an impact on fuel efficiency too. Departure time for the platform is also dependent on the arrival time of cargo for the vessels.

Once we started working with Onboard, we could objectively show that if a vessel departed too late, there would be an enormous impact on fuel efficiency due to strong tides and low drafts. To ensure that our vessels run with the greatest possible fuel efficiency under the tide, weather, and logistical circumstances they are in, we make sure the vessels fully loaded half an hour before low tide, and then we give the captains freedom to choose exactly when to leave, based on the factors such as wind and water depths. The customer then confirms the estimated time of departure. The captains take advantage of the tides to go to the platform using a minimum of fuel, unload, load, and return, all based on hard data to be as efficient as possible.

Once we started working with Onboard, we could objectively show that if a vessel departed too late, there would be an enormous impact on fuel efficiency due to strong tides and low drafts. To ensure that our vessels run with the greatest possible fuel efficiency under the tide, weather, and logistical circumstances they are in, we make sure the vessels fully loaded half an hour before low tide, and then we give the captains freedom to choose exactly when to leave, based on the factors such as wind and water depths. The customer then confirms the estimated time of departure. The captains take advantage of the tides to go to the platform using a minimum of fuel, unload, load, and return, all based on hard data to be as efficient as possible.

Very interesting! And what kinds of results are you seeing?

There has been a drastic and sustained drop of 33% in fuel consumption overall while working the same hours each day. But as there are a number of variables, there are still differences between voyages and captains. For example, one captain was going high speed at 18 knots to the island, and he started playing with the app to see how he could effectively reduce his fuel consumption. Now, when he doesn’t have any passengers, he goes at 6 knots, which uses dramatically less fuel. But when he has passengers, he goes at the normal speed. So this is an ongoing discussion and experimentation to see what we can do. It is also interesting in that the captains are becoming more and more involved in the process, and are coming up with their own ideas.

“There has been a drastic and sustained drop of 33% in fuel consumption.”

Has there been any impact on the relationship with your customer?

Yes indeed, as mentioned earlier, Onboard takes the guesswork out of reducing fuel consumption. The fact that we have certainty on what we are achieving makes a lot of the discussions we had around this topic unnecessary. And of course, this has a positive impact on the relationship.

What was the implementation and rollout process like?

The rollout was quite simple and straightforward. It was easy to get buy-in from the captains partly because their colleagues in another office were already using Onboard for a Walk 2 Work vessel, and partly because it is simply an easy system to operate. Also, we are doing the same voyage to Mittelplate repeatedly, which means we have a clear baseline to measure progress against.

Will the collaboration with Onboard change the way you do things in the future?

Yes. We want to be the best in class, and to do that we have to continuously innovate. Our new vessel will be outfitted with Onboard from the beginning, and will help us differentiate our offering as we pitch for new business - as competitors often claim to be able to be fuel efficient but cannot always show the hard data to back it up. On a broader note, there are a number of other initiatives we are pursuing internally to be best in class. Onboard is certainly helpful in being a differentiator, but it is not the only thing.

Finally, on a broader scale, what are your thoughts on the biggest trends in the maritime industry over the next few years?

Well the biggest and most visible trend is the energy transition. I think that is fairly obvious, and it is certainly a key consideration at Acta Marine as we look toward the future. Besides this, big data is in its early stages of adoption. Up to this point there have been some challenges unique to the maritime industry that have slowed this down a little, but I think it will play an increasingly important role in the coming few years.

This article was first published on the Onboard website.